Products

gabion retaining wall Back

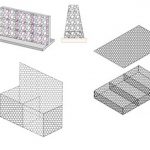

- Gabions manufactured from dimensionally stable panels of mesh that are formed by welding transverse and longitudinal wires at each and every intersection to form a grid.

- The gabion 39 box is then part assembled by hinging the face, back, sides and internal diaphragms to the base panel and the lid to the rear panel with ‘C’ rings or clips. The units are transported to site flat packed with lacing wire as standard for onsite erection.

- The Gabion 27 System comprises of units that are sub-divided into 686mm cells along the length of the cage. Construction is such that the base of the gabion forms the lid of the unit below. The base is extended by fixed dimensions on one face to allow for a predetermined stepping arrangement at each course. The base on the other face is flush, allowing for a flush faced wall to be constructed if required or coursing with a combination of flush and stepped faces.

- Gabion cladding units are a welded wire mesh box system that is configured in a different way such that the unit is sub-divided into cells both horizontally and vertically, allowing each course of cells to be filled. Normally the course lift is 686mm high but for overall heights that are not a multiple of 686mm, the cell height at the base can be manufactured up to 1m in height or the top cell reduced in height providing it is not less than 152mm.